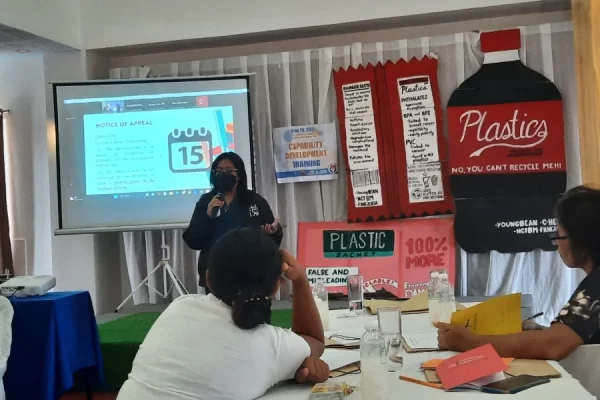

‘Most plastics used for in food, product packaging ‘not recyclable’ – ‘Balik scientist’

By: C-Help Team

Most plastics are not recyclable, according to a Filipino scientist, and while very few can be recycled, they are difficult to collect and separated from non-recyclable plastics.

Dr. Jorge Emmanuel, a 2016 DOST “Balik Scientist” talked about plastic and their recyclability in his affidavit that forms part of a landmark complaint filed in November, 2022 by 32 Filipino consumers against Unilever Philippines and 6 other fast moving consumer goods companies for dangerous plastic packaging and false and misleading recyclable plastic advertisement and labels before the Department of Trade and Industry (DTI).

Emmanuel has been teaching and conducting research in the Siliman University. His research interests are in various fields including plastic waste, plastics recycling, chemicals in food-contact plastics, global plastic pollution, and microplastics in marine life and debris.

Before being a Balik Scientist, in the 1970s and 1980s, he was an active member of two professional organizations in the United States related to plastics: the Society of Plastics Engineers and the Society of the Plastics Industry, now called the Plastics Industry Association.

Up for adjudication

The complaint, which has been endorsed for adjudication, will attempt to determine the culpability of some of the world’s major plastic polluters.

Aside from Unilever, the other companies named respondents to the consumer complaints are Coca Cola, Pepsi Cola, Nestle, Procter and Gamble, Colgate Palmolive, and Universal Robina Corp (URC). These manufacturing companies have been blamed for causing plastic pollution in the Philippines and the world.

In December, 2022, the DTI handed down Certificates to File Action following the failed mediation between the parties. Meanwhile, after a successful DTI mediation, the complainants and one of the companies – Procter and Gamble – agreed to continue the dialogue with the hope of reaching an amicable settlement.

As of this writing, the complaint for false and misleading recycling advertisement/label is on appeal at the Office of the DTI Secretary while the complaint for dangerous plastic packaging was endorsed to be filed at the Food and Drug Administration – Department of Health.

Nature and classification of plastics

According to Emmanuel, polymers are materials consisting of very large molecules composed of many repeating subunits. Thus, polyethylene plastic is comprised of long-chain molecules of many repeating ethylene units. While there are natural polymers such as wool or Silk, all plastics are synthetic (with a few semi-synthetic) polymers.

He said although there are many ways of classifying plastics, some classifications are especially relevant to the case filed before the DTI, he said.

“Plastics can be classified as thermoplastics or thermosets. Thermoplastics can be repeatedly heated, softened melted, and reshaped into new products. Thermosets—such as polyurethane, silicone, and epoxy polymers—can be heated only once during their processing; reheating will cause thermosets to break down, making them very difficult to recycle,” says Emmanuel Another system of classification, he said, through the Resin Identification Codes.

The term resin was used Interchangeably with plastic. The codes were developed in 1988 by the Society of the Plastics Industry (SPI) as a voluntaw coding system “to facilitate recycling of post-consumer plastics.” The codes are:

Polyethylene Terephthalate (PET or PETE)

High-Density Polyethylene (HDPE)

Polyvinyl Chloride (PVC or Vinyl)

#4 Low-Density Polyethylene (LDP E)

Polypropylene (PI)

#6: Polystyrene (PS or Styrofoam)

- Others

According to Emmanuel, in 1988, SPI introduced the resin identification codes, choosing a design that included three arrows forming a triangle with the resin identification number in the center.

The “chasing arrows” design was similar to the three-arrow Möbius loop design by Gary Anderson in 1970 which was adopted by the Container Corporation of America and other paper and carton companies to indicate that their packaging was made of recycled materials and could be recycled.

The symbol was adopted widely, became public domain, and has now become the symbol of recyclability worldwide. However, he said that only three of the seven classifications of plastics in the SPI resin identification system are commonly recycled.

Plastic recycling defined

Emmanuel explained that the vast majority of plastics are derived from fossil fuel. The life cycle of plastics involves the generation of hazardous waste, huge emissions of greenhouse gases, and damage to the environment during fossil fuel extraction, production from fossil fuel of basic chemical components in chemical refineries, production from chemical components of the baste building blocks (monomers, reagents, additives etc.) in petrochemical plants, production from the building blocks of polymer resins in polymer production plants, production from polymer resins of plastic products, plastics manufacturing facilities, transportation and distribution of both chemicals during production and of the final products, consumption of the products, and their disposal as plastic waste.

Made to last ‘forever’

“Plastics take hundreds of years to decompose completely so the 9 billion tons of plastics produced globally since 1950 are still somewhere in the environment, on land and in our rivers and oceans, except for the plastics that have been burned creating some of the most toxic pollutants known to science as well as toxic ash”.

According to Emmanuel, after some decades to a hundred years, plastics break into tiny pieces called microplastics that are found today in our fish, drinking water, beverages, food, and in the air.

“As they cycle in the environment, microplastics attract poisonous chemicals including cancer-causing substances, contaminants that can cause genetic mutations, persistent organic pollutants, endocrine disrupting compounds, and other toxic substances. Since microplastics will take hundreds of years to fully decompose, humans and animals will be exposed to microplastics and the toxic substances with them for many generations to come. Recycling should take into account this life cycle of plastics,” he stressed.

According to Emmanuel the plastics, petrochemical, and plastic product industries have promoted, as a potential solution to plastic waste, the process of chemical recycling wherein plastic waste is chemically converted using a variety of technologies into basic chemicals that can be used to produce the original plastic. “If the chemicals are used to produce other materials, the process is referred to as feedstock recycling. These processes have not been widely used due to high energy consumption, adverse environmental impacts, and very high costs,” he pointed out.